Ultrapure water: the essential raw material for PtX technologies

Ultrapure water plays a central role in all PtX technologies, especially in the production of green hydrogen by electrolysis. This high purity water is almost free of impurities such as organic matter, bacteria, particles and dissolved gases and has a very low conductivity of typically 0.055 μS/cm, making it ideal for use in sensitive processes such as PEMElectrolysis makes. Pure water is obtained from different source waters, which can vary greatly in quality depending on the origin. This variety requires a customized pure water treatment to remove all unwanted minerals and gases that could otherwise disrupt the electrolysis processes.

The importance of ultrapure water for PtX processes

The importance of ultrapure water for PtX processes cannot be overstated: without the right water quality, salt deposits can form on the membranes and electrodes of electrolysers and significantly affect their efficiency and service life. Therefore, process-oriented pure water treatment is not only an essential criterion but a critical success factor for the sustainable production of synthetic fuels.

From raw water to ultrapure water

When planning a water treatment plant, seamless integration into the PtX system is crucial. These include, for example, location-oriented planning in the overall system, control technology linking via specified communication interfaces, uniform manufacturers of plant components and consistent documentation. When planning a water treatment plant, the LCOE (levelized cost of electricity) must also be considered, which includes not only the investment costs but also the running operating costs. This includes energy and media consumption, waste water quantities, operating materials and service costs.

The treatment of raw water for hydrogen production by means of electrolysis is carried out in several process stages in a specific sequence, which is adapted to the local water quality in a detailed engineering. Different steps are used, such as:

- Pre-filtration by backwash filter, gravel filter or ultrafiltration

- Removal of the hardening agents calcium and magnesium by ion exchange softening systems (alternatively antiscalant dosage for hardness stabilization)

- CO2 removal/binding by membrane degassing or soda water

- Desalination by > 98 % by reverse osmosis (RO)

- Full desalination by means of the 2nd reverse osmosis stage or electrodeionization (EDI)

- Process water recycling plants for continuous desalination to < 0.1 μS/cm and particle filtration to below 1 μm

- Degassing systems for the removal of H2 and O2

- Process water storage system with storage tank and pressure booster systems

- Process water cooling device (optional)

Purity water qualities that vary due to the process:

| Quality parameters | Limit value |

| Conductivity Silica Total iron Sodium and potassium Particle concentration | < 0,1 µS/cm < 100 µg/l < 100 µg/l < 20 µg/l Particle-free |

Christopher Lenz

Business Development Manager bei EnviroFALK

More info about EnviroFALK Pure water systems for PEM electrolysis, the heart of hydrogen production in power-to-X technologies

EnviroFALK is all about solutions for water treatment in hospitals, laboratories and selected industries. In addition, the experts are developing ultrapure water systems that supply electrolysers with highly pure water. This enables the company to produce hydrogen reliably and efficiently.

The quality and availability of ultrapure water is crucial for the PtX process. High service availability and short repair times (Mean Time To Recover – MTTR) as well as high system availability (Service Level Agreement – SLA) are essential for water treatment plants. To minimize outages, measures such as redundancy of critical components, optimized spare parts inventory, use of proven components and accurate monitoring of process parameters are required. These strategies allow for system availability of over 99%. EnviroFALK offers a wide range of high-quality components for maximum process reliability.

EnviroFALK pure water process systems are characterized by their modular design, which allows flexible integration into existing plant concepts. This modularity offers the advantage that the different process stages can be arranged individually according to spatial and process-technical requirements. Whether next to each other, on top of each other or in separate rooms – the systems can be optimally adapted to the respective conditions.

In recent years, EnviroFALK has developed and delivered numerous application-oriented pure water process systems for PtX projects through close cooperation with renowned manufacturers of electrolysis systems.

From the early beginnings in 2012 to today, more than 100 pure water process systems have been implemented in different concepts and performance levels for various PtX projects. These contribute significantly to the establishment of hydrogen as a sustainable energy source and thus to an environmentally friendly and contemporary production of energy.

The construction of one of the largest, flexible hydrogen plants in the world at that time with an electrical output of 6 MW took place in 2015 in the business park Mainz-Hechtsheim. Today, up to 1,000 Nm3 of green hydrogen are produced every hour from excess electrical wind energy using PEM electrolysers from Siemens. The hydrogen produced is stored on site and then fed into various applications, such as transport, industry and the natural gas network. The raw material water is supplied with a 1,000 l/h pure water system and freed of the finest particles and dissolved salts by means of a 4,200 l/h process water purification system.

In 2023, Air Liquide and Siemens Energy built the “Trailblazer” project at the Oberhausen site – a 20 MW PEM electrolyser for the production of green hydrogen. The Trailblazer supplies key industries such as steel, chemicals, refineries and transport with 2,900 tonnes of green hydrogen per year and oxygen via an existing hydrogen pipeline. EnviroFALK supplied a circuit system with a throughput capacity of 30,000 l/h.

- Windgas Haßfurt GmbH (PtG project)Electrical power 1.25 MW from wind energy, hydrogen production about 200 Nm 3/h, pure water system 300 l/ h, recycling cleaning 600 l/ h

- Salzgitter Flachstahl (PtG-Projekt)Electrical power 2.2 MW from wind energy, hydrogen production about 400 Nm 3/h, pure water plant 900 l/h, recycling cleaning 4,200 l/h

- Ludwigshafen (PtC project)Electrical power 54 MW hydrogen production 8000 t/a, pure water plant 10,500 l/h, recycling cleaning 150,000 l/h

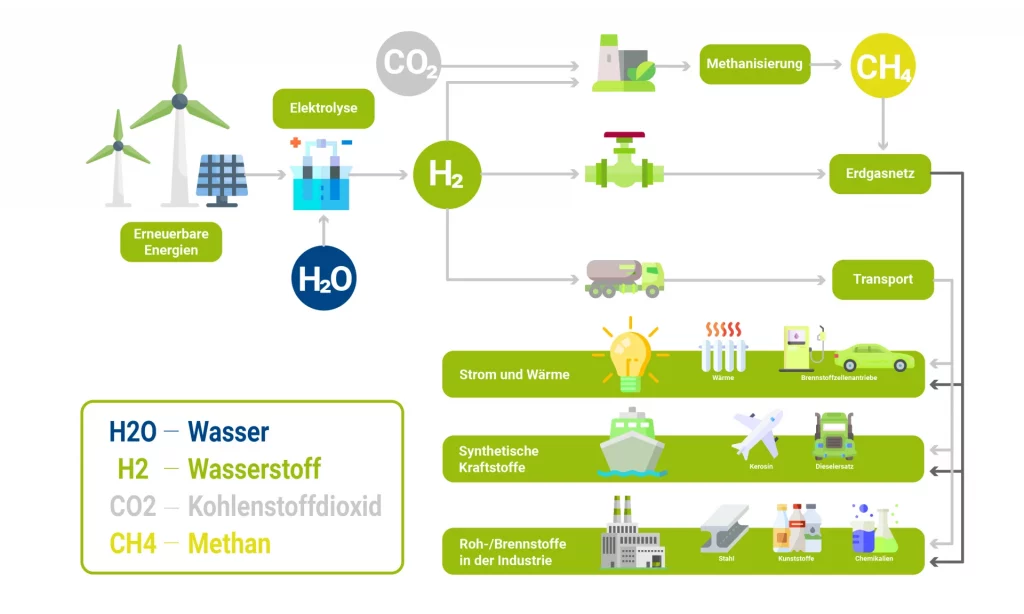

Power-to-X is a generic term for technologies that allow surplus electricity from renewable energy to be processed and stored, thus replacing fossil fuels (Figure 1).

- Energy carrier gas – power-to-gas (PtG)

- Liquid fuels – power-to-liquid (PtL)

- Chemical Raw Materials – Power-to-Chemicals (PtC)

In the PtG process, excess green electricity is used to produce so-called “green hydrogen” which, as an energy source of the future, leaves only water as a combustion residue.

Different types of electrolysis systems, called “electrolysers”, are used here to split water into its chemical components hydrogen (H2) and oxygen (O2) by means of electrical current. Polymer electrolyte membrane electrolysis (PEM) (Figure 2) plays a major role due to its resistance to the load changes of fluctuating renewable energies, as well as its high efficiency and fast reaction times.

After electrolysis, H2 is compressed to store and transport it. Green hydrogen is used as an energy carrier in fuel cell vehicles and industrial plants, as well as as a raw material in the chemical and pharmaceutical industries.

Hydrogen can be fed into existing natural gas networks for transport and further use under certain conditions. However, due to its lower energy density, this is only possible in limited quantities. For the injection of larger quantities, H2 is first produced from methane (CH4) by methanation and then fed into the natural gas network, where it can be used for heating purposes and/ or for electricity generation.

In addition, gas-powered cars and trucks can also be fuelled with green hydrogen and thus operate almost climate-neutral.

Green hydrogen is also used in the production of synthetic liquid fuels. The PtL technology uses excess electricity to produce a synthesis gas of hydrogen and carbon monoxide, from which liquid synthetic fuels (e-fuels) are produced. This technology allows for the gradual replacement of petrol and diesel from petroleum. Synthetic fuels for aviation and shipping can also be produced. One major advantage of this technology is the use of existing infrastructures, such as gas stations and transport systems.

Since the synthetic production of e-fuels from green electricity binds the same amount of CO2 as it releases during combustion, these fuels are considered climate-neutral.

Based on the PtG process, the PtC technology uses green electricity and the synthesis of hydrogen with CO2 and nitrogen to produce chemical raw materials that are intended to replace fossil fuels such as petroleum and natural gas. Examples are plastics, detergents and additives which are important in many industries.

The progressive global warming requires a shift from finite fossil fuels to clean, renewable energies from water, solar, wind and biogas plants.

Wind and solar energy are the most important sources of renewable electricity generation. However, a major problem of the future energy industry due to fluctuating renewable energies is storage. The power grid is not able to store energy when there is a shortage of demand, which means that the plants have to be regulated and therefore work inefficiently. Although pump storage plants and batteries have been used for short-term electricity storage of the so-called eco-power, these are not sufficient to secure the energy supply in the long term.

The planning of innovative PtX projects is a crucial step on the way to a climate-neutral Europe by 2050. These projects help reduce dependence on fossil fuels and diversify energy supplies. The first global PtX atlas, created by the Fraunhofer Institute for Energy Economics and Energy Systems Technology, shows the enormous potential. Especially in regions rich in renewable energy sources. Such projects can transform not only Europe but also the global energy infrastructure and create a win-win situation for the environment and economy.

EnviroFALK is prepared to support PtX projects with state-of-the-art ultrapure water systems and thus further advance climate neutrality.